Posted by Bixpy on Apr 5th 2022

The Complete Guide to How Outboard Motors Work

If you are new to boating, you may see a motor and assume that all of them are the same thing. However, you will hear terminologies like outboard engines, inboard engines, tiller, or skeg used when looking at motors. With those terms being common amongst seasoned watercraft owners, it may confuse you when you research them yourself.

But all these terms matter when you are looking at an outboard motor because it is widely employed in the maritime sector, and it's essential to comprehend how all their many elements interact. This is the complete guide to how outboard motors work, so you know what you need to keep an eye on.

Outboard Motor Components

The most frequently used method for motorizing and operating a watercraft is by utilizing an outboard motor. It is an effective way to cruise in the water because of its propulsion system. Additionally, it can be much smaller than an inboard motor, which can limit the amount of room you have when relaxing on your boat.

You will mount the motor on the outside of the transom, allowing maximum capacity for you and your patrons. There are plenty of advantages to using an outboard motor, including impressive horsepower, simple installation, and the ease of prolonged preventative maintenance.

Outboard motors are available in two configurations: two-stroke and four-stroke. Previously, the distinctions between these two versions were obvious. However, current two- and four-stroke motors are considerably more equal in terms of dependability, weight, acceleration, and fuel efficiency because of technological developments.

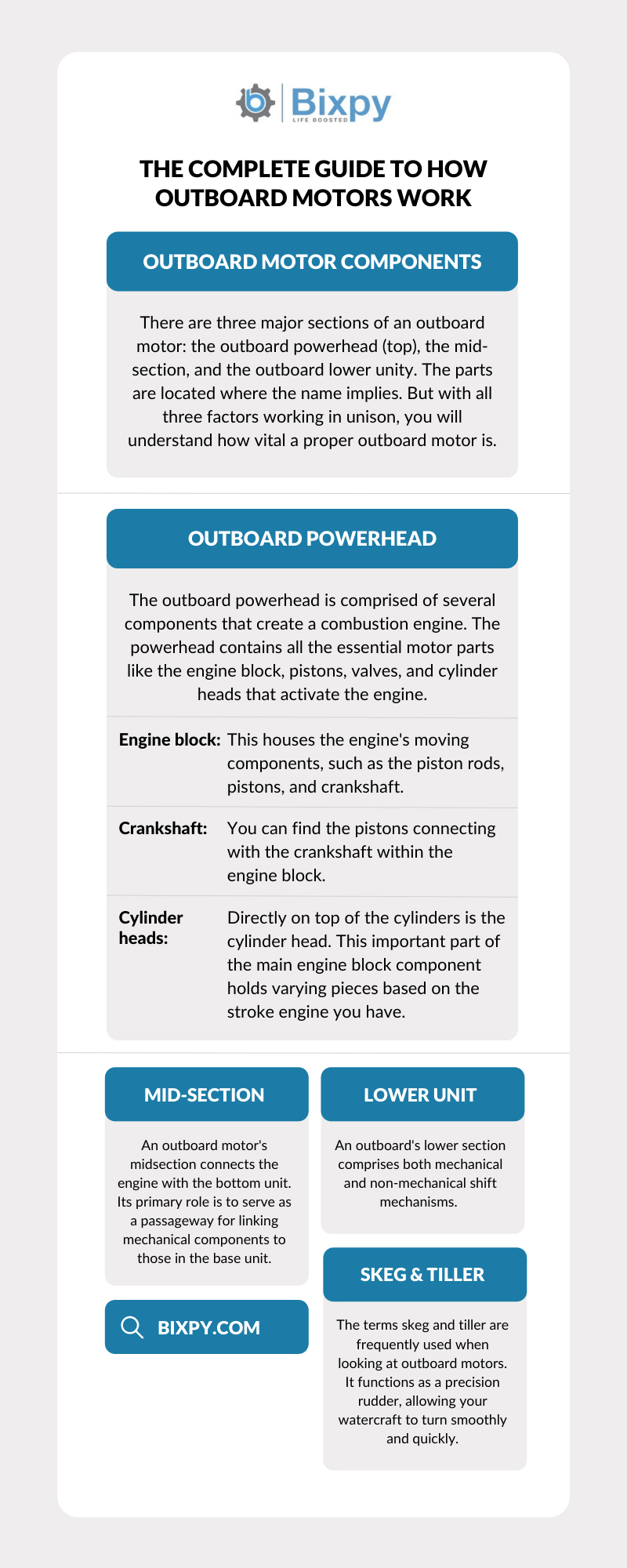

There are three major sections of an outboard motor: the outboard powerhead (top), the mid-section, and the outboard lower unity. The parts are located where the name implies. But with all three factors working in unison, you will understand how vital a proper outboard motor is.

Outboard Powerhead

The outboard powerhead is comprised of several components that create a combustion engine. The powerhead contains all the essential motor parts like the engine block, pistons, valves, and cylinder heads that activate the engine. Here is how those parts work to get the outboard motor running smooth.

- Engine block: This houses the engine's moving components, such as the piston rods, pistons, and crankshaft. It also includes the cylinders that hold the pistons. The engine's strokes occur inside the engine block and differ depending on which stroke engine it is.

- Crankshaft: You can find the pistons connecting with the crankshaft within the engine block. The crank revolves around the pistons to produce energy as they travel back and forth. Piston rods link the piston together to the crankshaft. When the crankshaft rotates, the piston rods start firing, causing the pistons to revolve within the cylinders.

- Cylinder heads: Directly on top of the cylinders is the cylinder head. This important part of the main engine block component holds varying pieces based on the stroke engine you have. They usually camshafts, cams, valves, and spark plugs.

Cooling tunnels inside cylinders, cylinder heads, and engine block are severe factors. These are essentially passages that let heat-absorbing water circulate across the powerhead. This prevents the engine from overheating and melting the metal.

A thermostat positioned in the cooling tubes regulates the water temperature running through the engine. The thermostat's function is regulating the engine’s temperature, as problems can arise if the engine gets too hot or too cold.

Mid-Section

An outboard motor's midsection connects the engine with the bottom unit. Its primary role is to serve as a passageway for linking mechanical components to those in the base unit.

This portion features a bracket that secures the motor to the transom. This enables the motor to spin in various directions so you can steer the boat.

Smaller vessels generally include a tilt feature that lets you raise the engine up and out of the water. For your larger outboard motors, you may find out that operates with the simple click of a button.

The driveshaft housing, which acts as the engine's central structural portion, is similarly situated in the midsection. The driveshaft itself provides power to the lower unit with torque and rotation, giving the propeller juice to run. A water tube links to the lower portion, lowering the temperature of the powerhead with cooling water.

In summary, the mid-section of the engine is the bloodline, seeing as it connects everything that allows you to operate the boat with relative ease.

Lower Unit

Like the powerhead, several parts are needed to power the lower unit of an outboard motor. It consists of the following: driveshaft, propshaft, clutch dog, bearings, shift mechanisms, gear set, seals, and shims.

An outboard's lower section comprises both mechanical and non-mechanical shift mechanisms. The shift mechanisms control the propeller's rotation. Devices like a horizontal cam, a vertical cam, a cradle, and a yoke are examples of mechanical shift systems. An electric, hydroelectric, hydro-mechanical shifts are examples of non-mechanical shift mechanisms.

The lower unit's gears get rotational movement by imparting pressure to the teeth of another gear. Gears turn the torque of the engine by 90 degrees to propel the propshaft in an outboard lower unit.

Skeg & Tiller

The terms skeg and tiller are frequently used when looking at outboard motors. It functions as a precision rudder, allowing your watercraft to turn smoothly and quickly. It also keeps the propeller from entangling in water debris or other threats that you may encounter.

The tiller is also integral in guiding the boat. A lever attaches to a rudder post, letting the driver effectively maneuver the boat without complications.

Understanding the complete guide to how outboard motors works now lets you focus your attention on precisely what you want. Bixpy has an impressive selection of inventory that includes one of the finest outboard motor kits you can buy. A Bixby outboard motor is the fastest, most efficient way to motorize your watercraft. With our outboard motors being some of the lightest on the market, it's ideal for the smaller watercraft while not losing any power! Our knowledgeable and friendly staff will be more than happy to assist you with any of your needs, so feel free to reach out to us today!